How it works

5NaClO2+4HCl →4ClO2+5NaCl+2H2O

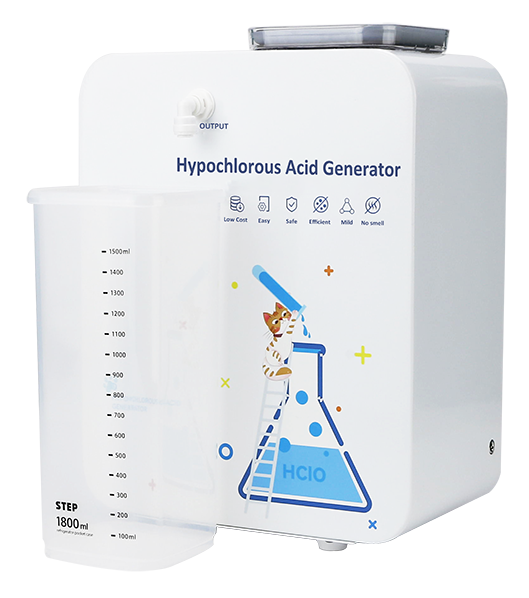

Composition of RC series chlorine dioxide generator

- Feeding system

- Reaction system

- Control system

- Mixed absorption system

- Security system

- Residual liquid automatic processing system

Raw materials and the consumption

Sodium chlorite: (HG/T3250-2001 first grade industrial product, content ≥78%);

Hydrochloric acid: (GB320-2006 industrial first grade product, concentration ≥31%)

2.2g of sodium chlorite, 6.75g of hydrochloric acid (to produce 1g of chlorine dioxide)

Performance characteristics

- Using sodium chlorite and hydrochloric acid as raw materials to prepare liquid high-purity chlorine dioxide disinfectant, the purity of chlorine dioxide is ≥95%, and the conversion rate of sodium chlorite is ≥95%.

- The reactor adopts multi-grade industrial titanium-based alloy and fluoroplastic materials, with a long service life.

- The material transportation adopts the international famous brand precision metering pump and constant back pressure device, so the raw material measurement is accurate.

- The control system adopts intelligent or PLC control system, which is operated by touch keys.

- Equipped with RS485 interface, which can realize remote transmission and remote monitoring of equipment operating status signals.

Application

- Wastewater disinfection (municipal, hospital): It can kill most of the bacteria in the water, such as E. coli and various types of streptococci.

- Water purification and disinfection: Killing algae in water

- Fruit and vegetable washing and disinfection.

One water plant chooses our generator to replace Prominent sodium hypochlorite machine on 2017 as photo below.