Features

(Compare with liquid Chlorine storage& Sodium Hypochlorite generator)

- Raw Material: Salt, Electricity

- Output: Chlorine gas, Hypochlorous Acid Anolyte

- Chlorine gas generated on demand

- Eliminate chlorine storage and transprotation risk

- sodium hypochlorite as back-up disinfectant

- 50% cost less consumption of raw materials than NaCLO generator

- 100% safe: No risk of any hazardous Chlorine storage & operation

- Skid Mounted Plug-Play design

- Remote Monitor & Control

- Environmentally Friendly

- Ability of Counter-Terrorism

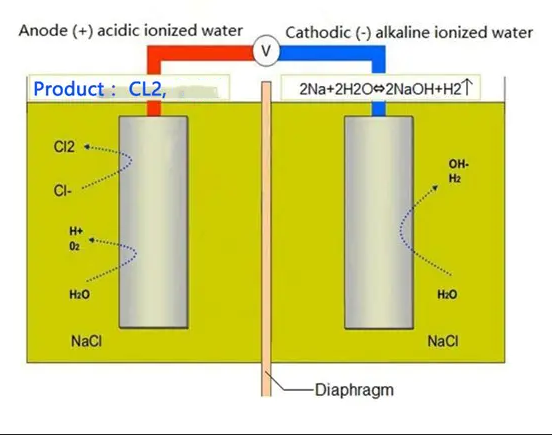

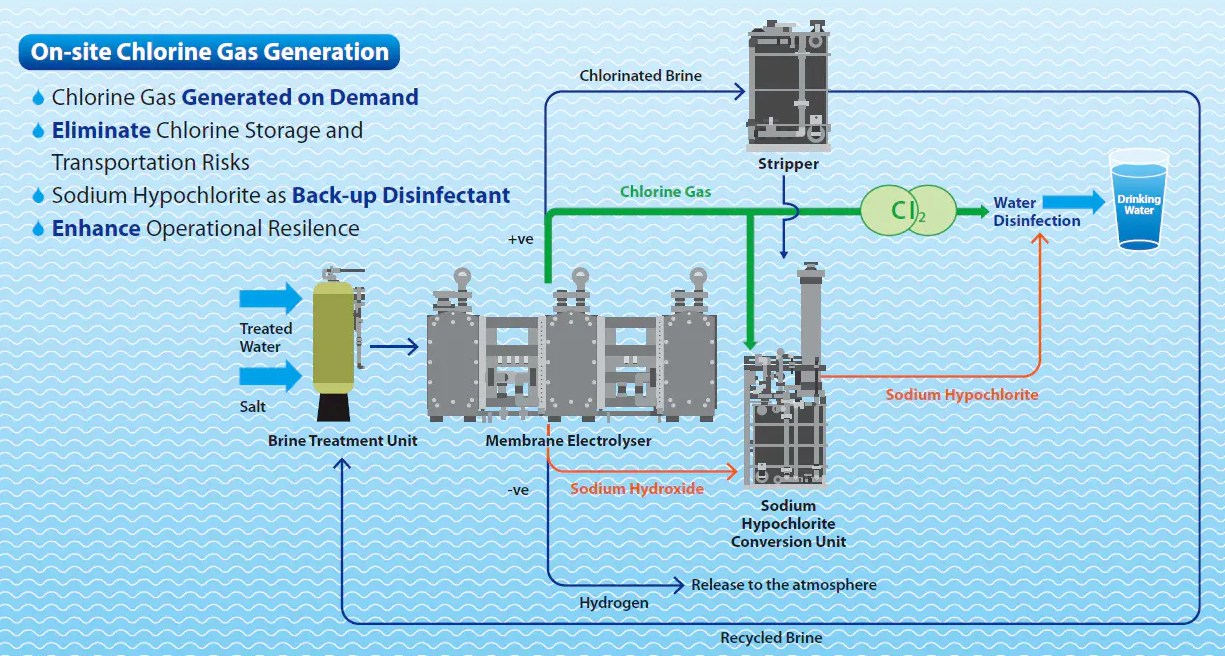

- Chlor-alkali process

How it works

Chlor-alkali technology.

Salt (NaCl) water Brine is electrolyzed in an electrolytic cell by ECA technology, Chlorine gas (Cl2) is generated in the anode cell, and then immediately dosing into water for disinfection treatment on the plant site; None Storage, None hazardous risk. It can be used widely on all kinds of water treatment plants.

Meanwhile, hydrogen H2 and A little of NaOH liquid is generated and discharged by cathode cell.

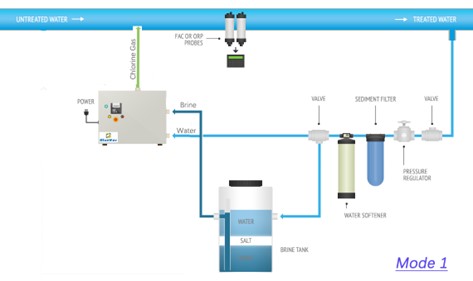

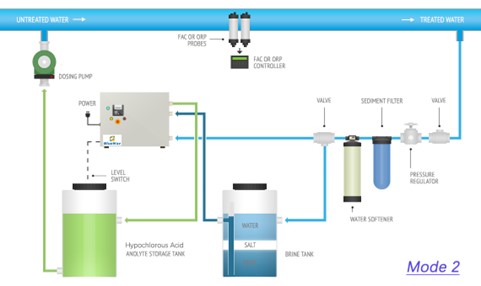

To satisfy client’s different requirements on water plant site, The system is able to work on two modes as following:

Features

- Specification Data

| Parameter | Specification | Unit |

| FAC | 50-5000 | g/h |

| Electricity consumption | 8 | Kw.h/kg.CL2 |

| Sal Consumption | 1.6 | Kg/kg.CL2 |

| Generator Dimension | ||

Model List Of BCL Generator

|

Model |

FAC

g/h |

Installed Power

kw |

Salt

Consumtion Kg/kg CL2 |

AC Power

Consumtion Kg/kg CL2 |

Floor Space

㎡

|

| BCL-50 | 50 | 6.0 | 1.6kg | 8kw |

3m*3m |

|

BCL-100 |

100 | 9.0 | 1.6kg | 8kw | |

| BCL-200 | 200 | 12 | 1.6kg |

8kw |

|

|

BCL-300 |

300 | 15 | 1.6kg | 8kw | 5m*3m |

| BCL-400 | 400 | 12 | 1.6kg |

8kw |

|

|

BCL-500 |

500 | 18 | 1.6kg | 8kw | |

| BCL-1000 | 1000 | 24 | 1.6kg | 8kw |

6m*3m |

|

BCL-2K |

2000 | 35 | 1.6kg | 8kw |

10m*3m |

Client Project photos