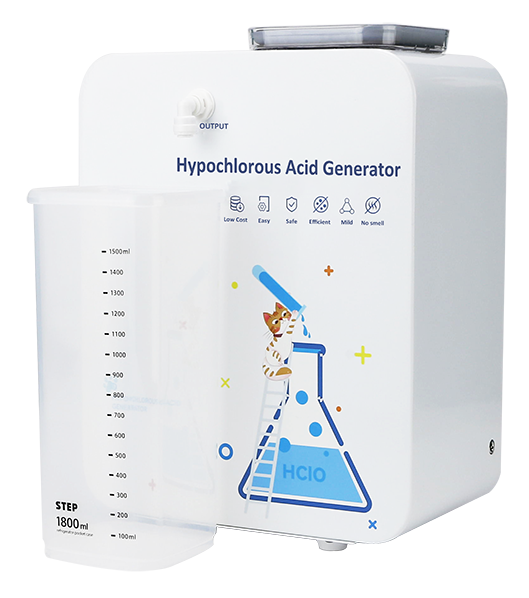

BH-T-50

How to make/produce anolyte hypochlorous acid disinfectant by BH-T?

Our equipment electrolysis of self-developed raw materials. In the advanced membrane, the Anode side produce output pure HOCL/Anolyte/EOW Electrolyzed Oxidizing Water for top Medical Grade application including HOCL Medicine. No residue. Non-toxic, Non-Irritating, No Drug resistance.

How to use BH-T hypochlorous acid Generator?

- Feed water

- Feed self-developed raw materials

- Power on

- the machine will start to produce Anolyte and Catholyte

Our advantages:

- The hypochlorite solution produced is medical grade and contains no impurities

- Adopt the exclusive patented technology of diaphragm electrolysis, more efficient electrolysis

- Small size and light weight

- Adjustable concentration

- Support customization

- Good price for batch dealer

Clean HOCL Solution Applications

- Skin disinfection

- Oral disinfection

- Nose disinfection

- sterilize medical equipment

- Food disinfection

- Seafood Cold-chain logistic Disinfection (up to-20℃)

- Airport/Hotel/School/Train/Bus/Office surface disinfection

- Animal stockbreeding

Medical grade hypochlorous acid generator equipment details

|

Project |

Unit | Note |

| Water intake pressure | <0.4Mpa |

No greater than normal tap water pressure |

|

Effective chlorine range |

10-500ppm | Can be controlled by adjusting the current, voltage, and salt addition frequency |

| Maximum current | 8.1A |

Recommended for use between 5-7A for best results |

|

Maximum power |

400W | It is recommended that the voltage adjustment should not exceed 36V (safe voltage) |

| Maximum Voltage |

220V 50-60HZ |

|

|

Temperature requirements |

0-50℃ | |

| Machine Service life |

8 years |

|

|

The core component electrode service life |

1000 hours | |

|

Optional |

Intercon | Internet connection by app |

| Probe-PH |

PH sensor |

|

|

Probe-ORP |

ORP sensor | |

|

RO unit |

||

|

Raw material 1kg |