The quality control of salt is the key point of operation management of sodium hypochlorite generator.

The results show that when the total amount of calcium and magnesium ions in salt is less than 30 mg/kg and the content of sulfate ions is less than 2000 At mg/kg, the electrode scaling can be significantly alleviated, the effective chlorine, salt consumption, power consumption and equipment loss of the generator unit can be reduced, and the precious metal coating in the electrode can be avoided because of frequent pickling and damage, while other impurities have no obvious adverse effects on the operation of the generator equipment and product quality. Therefore, the selection of uniodized salt that meets the requirements of calcium, magnesium and sulfate as the generator raw material has the highest comprehensive benefit.

The total design scale of a foreign water plant is 400,000 m/d. The water plant uses conventional processes to produce water. The sodium hypochlorite disinfection process will be reformed in 2020-2021, and the disinfection method will be changed from the original liquid chlorine disinfection to online preparation of sodium hypochlorite disinfection. Taking the use effect of different raw material salts in sodium hypochlorite generator of the water plant as an example, this paper analyzes the economy and rationality of the selection of raw material salts, in order to provide reference for the construction and operation of related projects.

Sodium hypochlorite generator process overview

Online preparation of sodium hypochlorite disinfection process with sodium hypochlorite preparation dosing system as the core, The sodium hypochlorite storage tank level closed-loop control generator automatically operates, and protects according to the hydrogen concentration and equipment operating status, such as the storage tank level is high/low, the generator liquid temperature is high, the electrolytic tank level is low, the electrolytic voltage is high/low, the electrolytic current exceeds the limit, and the rectifier power supply is interlocked to achieve unattended PLC automatic control.

According to the calculation of the amount of chlorine injection, the water plant selects 3 sodium hypochlorite generators (each 20kg/h),2 used and 1 standby, each generator is composed of 4 sets of parallel electrolytic cells, each set of electrolytic cells (5kg/h) is separately injected and powered, and 1 set of electrolytic cell system can be manually removed if it fails, without affecting the use of other parts.

The electrolytic cell uses a plate film electrode, the electrode material is titanium decruthenium-iridium oxide coating, and the anode and anode are added with positive and anionic films. Under the action of direct current electric field,3% brine produces sodium hydroxide and hydrogen in the cathode, and chlorine gas in the anode. The electrolytic product chlorine gas and sodium hydroxide are mixed at the outlet to produce sodium hypochlorite solution with an effective chlorine concentration of 0.8% Discharge hydrogen. Due to the initial separation of electrolytic products in the reaction process, the hypochlorite can be avoided from the electrolytic disproportionation reaction in the cathode chamber and the chemical disproportionation reaction in the anode chamber, and the generation of chlorate can be effectively reduced.

Equipment and detection methods

During the production test, the operation of the generator is divided into two stages, the first stage is the initial stage, the operation time is 8 months, the use of uniodized refined salt, the salt meets the “edible salt” (GB/T5461-2016) in the indicators, the physical and chemical indicators meet the refined salt level and above standards; The second stage is the test stage, the operation time is 8 months, the two generators use sanitary disinfection water treatment salt and non-iodized dry salt, the product standard is “Water treatment salt” QB/T56852022) and “dry edible salt” Q/GZYY0002S-2020).

Detection method

Iron, manganese, calcium, magnesium, bromate, potassium ferricyanide, compound, trichloramine, titanium, sulfate in soft water, salt water, sodium hypochlorite, pickling solution: Ruthenium, iridium detection refer to H/T345-2007,GB/ T11911-1989,GB/T7476-1987,GB/T 11905-1989, GB/T5750.10-2006 ion spectrometric method – Carbonate system eluent, GB/T13899-1992, GB/T5750.5-2006 isonicotinic acid – pyrazolone spectrophotometry, GB/T5750.11-2006N, N-diethyl-p-phenylenediamine (DPD) spectrophotometry Degree method, GB/T5750.6-2006 salicylfluorone spectrophotometry, GB/T5750.5-2006 barium chromate spectrophotometry (cold method)HI7002014, HJ700-2014.

Results and discussion

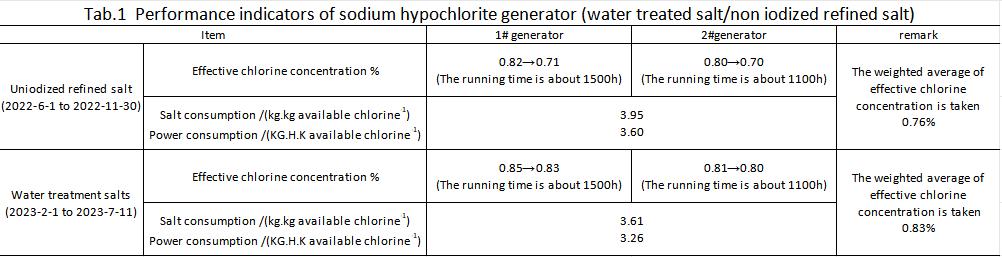

Since the generator was put into operation, in order to ensure the efficient operation of the equipment, the three products of ordinary uniodized refined salt, uniodized dry salt and water treatment salt have been analyzed for a long time, and the results are shown in Table 1 and Table 2.

Compared with uniodized refined salt, water treatment salt can alleviate the phenomenon of electrolytic scaling, and in the same running time, The average effective chlorine concentration of the product decays more slowly, the average effective chlorine decay rate of 1.3×10%/h is only 18% of the original decay rate (the effective chlorine decay rate of 7.3×10-%/h when the uniodized salt is used as the raw material), the salt consumption decreases by about 8.5%, and the power consumption decreases by about 9.4%. When the available chlorine decreases by 0.11%, pickling is required for 1507h in total operation; when the available chlorine decreases by 0.11% in water treatment salt, pickling is required for 8462h in total operation. According to the operation time of 8.2h/d of a single generator, the pickling cycle is 34 months after using water treatment salt. The original pickling cycle is 6 to 8 months, which is equivalent to more than 4 times the pickling cycle.

As can be seen from the analysis in Table 2, the variation range of sulfate ions is wide, and raw salt denitration is more complicated. Therefore, the control of sulfate is difficult, and it can only be controlled within 2000mg/L according to the strictest standard (QB/T5685-2022). Calcium and magnesium ions are not restricted in the current salt standards. The relevant standards in the chlor-alkali industry “Industrial salt” (GB/T5462-2015) and “Salt for ionic membrane caustic soda” QB/T5270-2018) restrict calcium and magnesium ions as follows: The total amount of calcium and magnesium ions required for superior industrial wet salt is <3000mg/kg, and the refined wet salt for ionic membrane chlor-alkali requires calcium <1500 mg/kg, magnesium <1000 mg/kg; The limit value of calcium and magnesium ions in water treatment salts is about 10% of the above standards. From the actual use effect, even if the requirements of calcium and magnesium ions in water treatment salts are met, it is still easy to lead to electrode scaling. This is because the sodium hypochlorite generator of the water plant has not refined the raw salt, although the index limit requirements for chlor-alkali industrial salt are loose, but its impurity removal requirements for refined brine are higher, Guangxi salicylinization and chlor-alkali industry for the secondary purified brine index requirements for the total amount of calcium and magnesium ions ≤20μg/L and the actual operation of the sodium hypochlorite generator of the water plant shows that, When the total amount of calcium and magnesium ions in salt is below 30mg/kg, the total amount of calcium and magnesium ions in 3% brine can be close to 900g/L, and the electrolytic scaling phenomenon is significantly improved.

conclusion

(1) Sodium hypochlorite generator electrode scaling is shown as an increase in electrode temperature and electrolytic voltage, and a decrease in the effective chlorine concentration of sodium hypochlorite solution, but the decrease in temperature will also lead to an increase in electrolytic voltage. In the production and operation process, the operating state of the generator should be accurately judged according to the above changes, and abnormal conditions should be discovered and solved in time.

(2) After pickling, the effective chlorine concentration of the generator can be increased from 0.71% to 0.88% in the scale state, and the production and running time and dosage flow rate of the generator can be reduced by 19.3%, and the unit effective chlorine salt consumption and power consumption (direct current) can be saved by about 19.4% and 20.8%, respectively, with significant comprehensive benefits, but the pickling electrode will destroy the ruthenium and titanium in the electrode Precious metal coating, such as iridium, to shorten the life of the electrode, because the electrode cost accounts for the total investment of the equipment is large, so it is recommended to avoid scaling problems as much as possible, reduce the frequency of pickling.

(3) The main impurities that lead to electrode scaling are calcium, magnesium and sulfate ions in salt, and other impurities do not affect the health and safety of sodium hypochlorite. According to the actual production experience, it is recommended to control the total amount of calcium and magnesium ions in salt below 30mg/kg, sulfate ions below 2000mg/kg, and the hardness of 3% brine can be controlled below 3mg/ kg, and there is no obvious scaling phenomenon after 8 months of operation of the equipment.

(4) Comparing the above salt products, it can be found that because there is no strict implementation standard for the total amount of calcium and magnesium ions in salt products, the total amount of calcium and magnesium ions in salt products produced with high standards may be higher than that of salt products produced with low standards, and the price is higher. Therefore, it is recommended to choose uniodized salt with low calcium, magnesium and sulfate content on the basis of meeting GB2721-2015 Product.

From BLUEWAV

Reprinted from Wanfang Database Vol.50, No.2, Water Supply and Drainage Journal 2024.