Compared with cold storage and air conditioning storage, sand storage has low cost, simple operation and is suitable for small-scale storage. However, sand storage is greatly affected by the local environment and climate, especially in the later stage of storage, a large number of chestnuts will germinate, rot and lose their commercial value. There are no reports on improving the quality and controlling the germination of sand storage chestnut. The background of this paper is the post-harvest water bath treatment technology of chestnuts that the author learned when communicating with Professor Fabio in Italy. Certain intensity of water bath treatment before storage can affect the physiological metabolism of chestnuts during storage. The addition of NaCLO in water bath treatment has a good effect on inhibiting the decay and germination of chestnuts. The effect of different concentration of NaCLO water bath treatment on the storage effect of sand-stored chestnut was studied with Yanchang chestnut as the test material, in order to maintain the quality of chestnut, control the germination and prolong the storage life of chestnut by NaCLO treatment.

Test material

Castanea mollissima Blume cv.Yanchang was selected as the experimental chestnut. After normal harvest, the spina buds were removed in time, bagged and transported to the fresh-keeping laboratory, and treated with water bath with different concentrations of NaCLO.

Test method

NaCLO concentration Settings (calculated by effective chlorine concentration):100, 500, 1 000 mg·L-1

Water bath treatment: 21 kg chestnuts for each treatment were treated with water bath in an aqueous solution of different concentrations of NaCLO (water: fruit (V/V)= 3:2). When the pH value of the solution dropped to 5.0, the chestnuts were taken out and dried until the original quality was restored, then divided into 3 parts, each of 7kg, and sand stored in the farmhouse according to the traditional method. Sand storage chestnut treated with no NaC10 water bath was used as control.

Traditional sand storage method: Dig pits in a cool, dry place with good drainage. Each pit is 0.6 m deep and 0.5 m long and wide. A layer of clean river sand 0.06 m thick is laid at the bottom of the pit. The water content of wet sand is 90 g·kg-1 After the clean river sand, the remaining 3.5kg chestnut is mixed with sand and put into the pit, and then covered with 0.2m thick river sand and 0.25m sand. Spacing of each pit is 0.3m. When the underground temperature is lower than -2 ° C and the surface temperature is lower than -5 ° C, cover the chestnuts with 0.3m thick corn stalk weeds (insulation layer). When the underground temperature is lower than -2.5 ℃ and the surface temperature is lower than -7 ℃, it is necessary to cover with two layers of mulching film, and then cover with corn straw weeds to improve the insulation effect. When the surface temperature rises to 2 ° C and the surface temperature rises to 5 ° C, the mulch film is removed and only the corn stalk weeds are covered to keep the underground temperature stable.

Determination index and method

Samples were taken once a month, 50 particles were taken for each treatment, and the physical and chemical indexes were determined.

Determination of starch content 3, 5-dinitrosalicylic acid colorimetric method (DNS method)

Determination of soluble sugar by 3, 5-dinitrosalicylic acid colorimetric method (DNS method).

Determination of soluble protein content Coomassie brilliant blue G250 method.

To investigate the germination rate, 50~100 chestnuts were randomly selected, and the germination rate was calculated.

Fifty to 100 chestnuts were randomly cut from the middle cross to investigate the rot rate of chestnuts.

REDOX titration of ethanol content.

Data processing

The difference significance was analyzed by using SPSS software and Duncan’s new complex range test.

Results and analysis

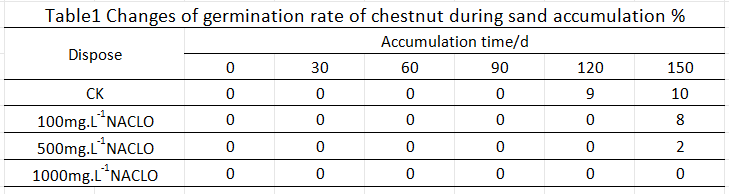

Effects of water bath treatment with different concentrations of NaCLO on germination rate of Sand storage chestnut

It can be seen from Table 1 that the germination time of control chestnut was earlier than that of NaCLO water bath treatment. The germination rate of control chestnut was 9% after 120 days of sand storage, while none of the chestnut treated with NaCLO water bath germinated. After 150 days of sand accumulation, the germination rate of control chestnut was 10%, the germination rate of 100 mg·L-1NaCLO water bath was 8% and 2%, respectively, and the germination rate of 1000 mg·L-1NaCLO water bath was not germinated, and the difference between treatment and control was significant (p≤0.01). And the germination rate was negatively correlated with the NaCLO concentration (r= -0.8184). In conclusion,NaCLO water bath treatment has a significant effect on inhibiting the germination of Shazang chestnut, and 1000mg·L-1 NaCLO water bath treatment completely inhibits the germination of chestnut.

Effect of water bath treatment with different concentrations of NaCLO on starch content of Sand storage chestnut

With the extension of storage time, the starch content of chestnut decreased gradually. The decrease rate of starch content of chestnut in the first 30d and 60-90d of sand storage was faster, indicating that the physiological metabolism was more vigorous and the starch hydrolysis rate was higher in these two periods. The variation trend of starch content of chestnut treated with NaCLO water bath was different from that of control. At the end of water bath treatment, the starch content of all treated chestnuts was lower than that of control, but there was no significant difference, indicating that the hydrolysis of starch was not significantly promoted during water bath treatment. The starch content of 100 mg·L and 500 mg·L water bath decreased rapidly in the first 90 days of sand storage, and then the decrease rate was slower, and was always significantly higher than that of the control (p≤0.05). However, the starch content of 1000mg·L-1NaCLO water bath in chestnuts decreased rapidly in the first 60 days of Shazang, and was significantly lower than that of other treatments and controls at 60 days (p≤0.05). During the subsequent storage process, the starch hydrolysis rate decreased and the starch content decreased slowly There was no significant difference between the starch content and control after d. After 150 days of storage, there was no significant difference in starch content among all treatments, but it was higher than that of control, and there was significant difference between 500mg·L-1 Naclo water bath treatment and control (p≤0.05). In conclusion, the water bath treatment changed the starch metabolism level of Shazang chestnut, and the water bath treatment of 100 and 500 mg·L NaCl0 reduced the hydrolysis rate of starch of Shazang chestnut, which was conducive to the maintenance of starch.

Effects of water bath treatment with different concentrations of NaCLO on soluble sugar content of Sand storage chestnut

In the first 30 days of sand storage, the soluble sugar content of treated and controlled chestnuts increased rapidly, reached the first peak on the 30th day, and then decreased. In the first 60 days of sand storage, the soluble sugar content of control chestnut was significantly higher than that of NaCLO water bath (p≤0.05), and the soluble sugar content of 100 and 500 mg·L-1 NaCLO water bath was similar, both of which were significantly higher than 1000 The value of mg·L-1NaCLO treated with water bath (p≤0.05) was consistent with the result of starch content in chestnut. After 60 days of sand storage, the soluble sugar content of chestnuts increased again and reached the second peak at 120 days. At this time, the soluble sugar content of chestnuts treated with 1000 mg·L-1NaCLO water bath was significantly lower than that of other treatments and controls (p≤0.05), but there was no significant difference between the soluble sugar content of chestnuts treated with 1000 mg· L-1NaCLO water bath and the control group. The results showed that 1000 mg·L-1NaCLO water bath treatment reduced the sugar content of chestnut in the sand storage stage, but 100 and 500 mg·L-1NaCLO water bath treatment only reduced the sugar content of chestnut in the sand storage stage, which had no significant effect on the sugar content in the later stage.

Effects of different concentrations of NaCLO water bath on soluble protein content of Sand storage chestnut

During the whole process of sand storage, the protein content of chestnut decreased gradually with the extension of sand storage time. The changes of soluble protein content in control chestnut could be divided into three stages: the physiological metabolism of chestnut in the first 60 days of sand accumulation was more vigorous, the rate of protein hydrolysis was faster, and the soluble protein content decreased rapidly, from 117.4g·kg-1 at the early stage of sand accumulation to 84.5g·kg-1 at 60 days. During the period from 60 to 120 days, the ambient temperature was low, and the chestnut had entered the physiological dormancy period, the physiological metabolism level was decreased, the consumption of substances was reduced, and the protein content was slowly decreased, and the protein content was 66.5 g·kg-1 on the 120 days of Shazang. After 120 days of sand storage, due to the rise of ambient temperature and the release of physiological dormancy, the level of physiological metabolism increased rapidly, the storage substances were consumed in large quantities, and the protein content decreased rapidly again. At the end of sand storage, the soluble protein content decreased to 48.9g·kg-1. The change trend of protein content of chestnut treated with 500 and 1 000 mg·L-1 NaCLO water bath was the same as that of control. The protein content of 500 mg·L-1NaCLO water bath was not significantly different from that of the control group, while the soluble protein content of 1000 mg·L-1NaCLO water bath was 91.1g·kg-1 and 91.1g·kg-1 at 60 and 120 days of sand storage, respectively The soluble protein content was 88.4g·kg-1, which was significantly higher than that of other treatments and controls (p≤0.05), and 77.1g·kg-1 at the end of sand storage. The variation trend of autogenous content of chestnut eggs treated with 100 mg·L-1NaCLO water bath was different from that of the control group, and it showed a linear decline during the whole process of sand storage. The soluble protein content of chestnut eggs treated with 100 mg·L-1NaCLO water bath was higher than that of the control group after 60 days of sand storage, and was similar to that of the control group after 120 days of sand storage. The above analysis indicated that 1000mg·L-1NaCLO treatment reduced the hydrolysis rate of protein during the storage of chestnut sand, which was beneficial to the preservation of protein.

Effect of water bath treatment with different concentration of NaCLO on ethanol content of Sand storage chestnut

At the end of water bath treatment, the ethanol content of chestnuts in each treatment was significantly higher than that in the control group (p≤0.01), and the ethanol content was significantly positively correlated with the NaCLO concentration (r ‘=0.994 6). This was due to the enhanced anaerobic respiration of chestnuts soaked in NaCLO solution, which resulted in the generation of ethanol and other fermentation products. The higher the NaCLO concentration, the more ethanol produced by anaerobic respiration. On the 30th day of sand storage, the ethanol content of each treatment was lower than that of the control, indicating that aerobic respiration dominated the process of sand storage, and the large amount of ethanol produced by anaerobic respiration gradually catabolized. In the subsequent sand storage process, the ethanol content of both NaCLO water bath treatment and control chestnut remained at a low level, and there was no significant difference between treatment and control.

Conclusion and discussion

The main problems of chestnut sand storage are rapid quality decline, serious decay, and rapid germination after dormancy release. The change of chestnut quality is mainly related to physiological metabolism of chestnut. Previous studies have shown that the physiological activity of chestnut during storage can be divided into three stages, namely, the active period after harvesting, the dormant period and the active period before germination. These three stages are closely related to the environmental conditions, especially the temperature conditions. In the early postharvest period, the ambient temperature was relatively high, and the physiological metabolism of chestnut was also relatively vigorous. At this time, the respiration of chestnut was vigorous, the starch hydrolysis rate was fast, the starch content decreased rapidly, the soluble sugar content increased, and the soluble protein content also decreased rapidly, indicating that the storage substances were consumed in this period. After entering the physiological resting period, the respiration intensity of chestnut decreased, the hydrolysis rate of starch and protein decreased obviously, and the content of soluble sugar also decreased. In the germination stage of chestnut, the starch hydrolysis accelerated, resulting in the soluble sugar content increased again, and the soluble protein content decreased again. The influence of NaCLO water bath treatment on the nutrient composition of chestnut is related to the concentration of NaCLO. From the perspective of the metabolism of starch and soluble sugar,500 mg·L-1 NaCLO water bath treatment has a better effect. From the perspective of the change of protein content,1 000 mg·L-1 NaCLO water bath treatment has a higher protein content, but the concentration is different compared with the control The NaCLO water bath did not reduce the protein content. Water bath treatment creates an anoxic environment. Under anoxic conditions, the activity of ethanol dehydrogenase (ADH) can be improved to varying degrees and ethanol can be accumulated, which has a similar effect to low oxygen or high carbon dioxide treatment. During storage, the accumulated ethanol in chestnut will gradually disappear without adverse effect on quality. NaCLO water bath treatment significantly reduced the decay rate and germination rate of Shazang chestnut. NaCLO is a commonly used disinfectant, which has been widely used in the disinfection of fruits and vegetables, seeds, etc. The combination of water bath treatment and NaCLO may make this antibacterial effect even better, in theory, the water bath treatment allows the accumulation of large amounts of ethanol inside the chestnut, and ethanol also has a disinfection effect. Some studies have shown that treating seeds with NaCLO solution can inhibit or promote seed germination, and the inhibitory effect or promotion effect on seed germination depends on the concentration of NaCLO solution. Hsiao et al. reported that NaCLO soaking treatment significantly improved the germination rate of Paspalum paspal-oides seeds of Sorghum halepense. This study showed that 100, 500 and 1 000mg·L-1NaCLO treatments could delay germination time and inhibit germination significantly, and the effect was proportional to the concentration of NaCLO. At present, the mechanism of NaCLO treatment on promoting or inhibiting seed germination is not clear and needs further study.

BLUEWAV’s NACLO is waiting for your purchase!

Reprinted from Forestry Research 2007, 20 (1) : 92~96