The main characteristics of seawater quality: seawater contains a variety of salts, the salt content of surface seawater is generally between 3.2% and 3.75%, with the increase of water depth, the salt content of seawater increases about; The main salt in seawater is chloride, which accounts for 88.7% of the total salt content. Seawater is slightly alkaline, with a pH of nearly 8. In today’s world, population increase, resource shortage, environmental deterioration, the ocean has extremely rich resources for human exploitation and will strongly promote the sustainable development of the world economy.

A domestic power plant adopts a seawater DC circulation system. The section between the water pump room and the main plant is made of reinforced concrete steel pipe with a diameter of 1820mm and a wall thickness of 14mm. Each of the two pipes is about 1500 meters long. Seawater is also used for cooling water of condenser oil cooler, water refill of injection tank and ash flushing water of boiler. Two years later, the maintenance operation found that the corrosion of the entire seawater pipeline is very serious, open the pipeline inspection, the first can see the swelling of the corrosion tumor, just opened the pipe for light green, long-term into brick red, is the corrosion product of iron, with a sharp hammer knock, even the tumor coating off, exposing a deep pit. After disassembling the secondary filter screen, it was found that the short pipe and flange were corroded obviously after the circulating water entered the water door, and the short pipe was a seawater resistant steel pipe. The valve plate of the condenser circulating water inlet electric butterfly valve has many corrosions and is more serious. The valve body and valve plate are made of special seawater resistant casting alloy, the sealing ring is natural rubber, and the other parts are made of stainless steel, which has strong seawater corrosion resistance. The stainless steel hook with a diameter of 20mm of circulating pump sewage grid is seriously corroded, and the stainless steel material is 1Cr13; Guide vane body and coupling are seriously corroded, and guide vane body material is HT200-2NiSB; The ejecting pump body part is corroded, the pump body material is HT250-2Ni/SB; The spool of the cooling water outlet valve of the oil cooler fell off, which was confirmed to be caused by corrosion of the spool through disassembly inspection. Later, when replacing the circulating jellyfish tube (wall thickness of 10mm) pressure gauge tube, it was found that the minimum thickness of the steel pipe here was 8.6mm, and the corrosion was very serious. The corrosion of inlet and outlet pipes of condenser with dissimilar metal coupling is more serious.

Cause analysis

According to the corrosion analysis, the corrosion of circulating water pipes is first caused by oxygen depolarization, and oxygen is a depolarization agent for seawater corrosion:

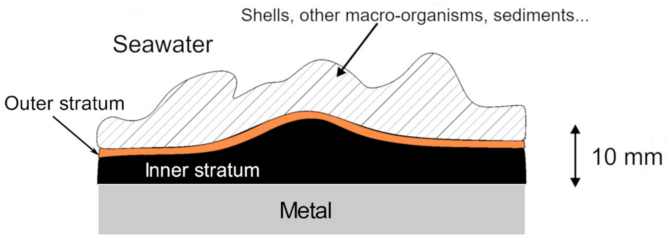

Due to the use of heavy anti-corrosion coating in the pipeline, the voidage is very low, so the corrosion can only be highly concentrated in a few points, plus this coating is thick, not easy to bubble, peeling, once off, corrosion occurs at the defect, corrosion products often can not be discharged outside the hole in time, the product is rapidly accumulated in the hole, resulting in hydrolysis, so that the medium in the hole salt acidification, hydrogen formation corrosion. Accelerate local corrosion until perforation.

In addition to the above reasons, the serious corrosion and perforation of the pipe section near the equipment is mainly due to the galvanic corrosion of cast iron and carbon steel, stainless steel and carbon steel in seawater. The heat transfer area of the shaft condenser is up to 500m and the surface of the bare titanium is connected to the carbon steel pipe covered by the heavy anti-corrosion epoxy coal asphalt coating, and the anode area is very small. The high-efficiency galvanic couple action of the large cathode and small anode will inevitably accelerate the corrosion and perforation of the seawater pipe. In addition, the flow rate of circulating seawater, chloride ion content and solid substances in the medium also have a great impact on the corrosion of pipeline materials: the higher the flow rate, the faster the corrosion rate of materials; The higher the chloride ion concentration, the faster the corrosion rate of the material. The higher the content of solid matter in the medium, the stronger the erosion force on the material. If these factors exist at the same time, the material is very prone to corrosion, and the corrosion rate will increase exponentially: although 10CrMoA1 stainless steel is a relatively good corrosion resistant material, because the circulating cooling water used in the power plant has a salt content of about 2.1%(mass fraction), and contains a certain amount of mud and sand, Under the dual action and erosion of high concentration of chloride ions and a certain amount of sand content, the protective coating is locally damaged, and the surface passivation of stainless steel is destroyed by erosion.

Protection scheme and effect

Through the analysis and observation of the whole water pipeline, it can be seen that the use of heavy protective coating alone cannot achieve the corrosion control effect required for normal production. Cathodic protection is one of the common methods to prevent seawater corrosion, but it is only effective in the full immersion area. Sacrificial anodes can be installed on the bottom of the ship or on metal structures in seawater, or cathodic protection with impressed current can be used. The elimination of cathode polarization due to the presence of H+ is conducive to the flow of electrons from the anode to the cathode, strengthening the corrosion process, that is, hydrogen depolarization corrosion. These crack sources quickly form cracks under the action of electrochemical corrosion and high stress generated in the manufacturing process, and the stress is concentrated at the crack tip, which plays the role of tearing the protective film. Under the alternating action of stress and corrosion, the crack develops in the direction of depth until fracture.

This time, we adopted the method of cathodic protection and coating combined protection, specifically: the circulating jellyfish tube from the steel pipe section of the pump room to the main factory terminal 10m in front of the plug plate adopts sacrificial anode protection; The other parts, including the rubber lined short pipe flanges connected between the inlet and outlet water pipes and the condenser, the valve covers, around the bellows, and the partition bolts of the water chamber before and after the condenser, are coated with the lining method. After the completion of the project, they are put into operation after receiving qualified experience. After one year of operation, the inlet pipe section to the inlet pipe section of the circulating water pump room, the inlet pipe section and the outlet pipe section, and the water chamber before and after the condenser were inspected. Among these pipe sections, there are the old pipe supporting the operation, the bellows treated with heavy protection, and the new pipe section replaced during minor repair, which are representative in the whole circulating jellyfish pipe: in addition to the coated lining and anode block in the bellows, The other parts are made of sacrificial anode method, and anodes are installed.

The inspection results show that the pipe section is well protected, the surface corrosion is greatly improved compared with that before protection, and the polar blocks dissolve normally. The surface condition of the corrugated pipe after heavy anti-corrosion treatment is also good.

Antifouling principle of electrolytic seawater to produce sodium hypochlorite

Seawater contains a large number of salts, mainly sodium chloride. Sodium chloride content is the highest, about 2.7%; It accounts for 77.8% of the total salinity, followed by magnesium chloride, which is about 0.38%, accounting for 10.9% of the total salinity. In the composition of seawater, the chloride ion content is the highest, and the chlorine degree is about 19%, accounting for 55% of the total ion content. Electrolytic seawater antifouling is the use of a special electrode electrolysis of seawater to produce effective chlorine, effective chlorine is a strong oxidizing agent, it can stun or kill the larvae and seeds of Marine organisms, so as to achieve the purpose of antifouling.

In order to make the electrolytic antifouling device run safely, continuously and efficiently, it is necessary to restrain the side reaction of unnecessary consumption of HCIO, pay attention to the discharge of hydrogen, and remove the calcium and magnesium salt deposits according to a certain cycle of pickling. There are two ways of electrolytic seawater antifouling, one is direct, the electrolytic anode is directly installed on the pipeline and seawater filter; The other is the indirect type (that is, electrolytic cell type), which is mainly used for seawater piping systems. The direct electrolytic seawater antifouling device is composed of rectifier, electrolytic anode, cable, etc. Direct electrolysis is to install the electrolytic anode directly in the seawater filter or seawater pipeline, and the seawater pipeline itself acts as the cathode. The large-scale electrolytic seawater antifouling system in coastal power plants and coastal factories is mainly composed of three parts: seawater electrolysis cell, power distribution equipment and seawater transportation, which belongs to the indirect electrolytic seawater antifouling device. Electrolytic seawater pollution prevention is closed operation, no harm to the health of the operator, will not cause pollution hazards to the Marine environment; The operation cost is low and the overall economic benefit is good.

conclusion

(1) The corrosion of carbon steel pipes in seawater with sand and high flow rate is more serious than in ordinary seawater, and the coating alone cannot achieve a good protection effect.

(2) The combined protection method of coating and cathodic protection can economically and effectively control the occurrence and development of seawater corrosion.

So far, great progress has been made in the research of Marine pipeline protection measures, but there are still many problems. Taking spraying anti-corrosion as an example, the small space of the manifold structure and some small parts can not be sprayed with machinery, only manual brushing can be used, and the construction quality is difficult to control. The internal anti-corrosion of some small containers is difficult to operate because people can not enter the field spraying, and the technology in this area is in urgent need of breakthrough. In addition, the factory prefabricated device in the field connection of the patching anti-corrosion insulation technology needs in-depth research, the field welding interface and patching external protection problems have yet to be solved, the use of some internal anti-corrosion effects also need to be tested time, internal spraying equipment needs to be improved.

BLUEWAV TECHNOLOGY CO.,LTD

Reference: Corrosion and protection of seawater circulating water pipes.