Starch is a kind of natural polymer compound with a wide range of sources and is an important raw material for industrial production. Starch is divided into natural starch and modified starch, natural starch is easy to age dehydration, limited application in industry, it needs to be denatured treatment, modified starch can better meet the special needs of production and life. Oxidized starch is the product of the reaction between oxidizing agent and starch in acidic medium or alkaline medium. Oxidized starch can not only improve the color and taste of food, but also change the characteristics of food, which is widely used in food industry. Sodium hypochlorite is a common oxidizing agent that oxidizes the hydroxyl group in starch, which breaks the starch molecules and produces some colored compounds, such as phenol or furfural. These compounds can be detected by spectrophotometry to determine the starch content. Sodium hypochlorite is widely used because of its cheap price, abundant source, simple operation and little residue. The amount of sodium hypochlorite used in industry is large, and the transportation cost is too expensive. BLUEWAV sodium hypochlorite generator can be used for on-site preparation, which is convenient to use and simple to operate.

Sodium hypochlorite oxidized starch preparation technology

In actual production, oxidized starch is mainly produced by wet process, and sodium hypo is the oxidant used. Starch and oxidizer in acidic, alkaline or neutral solution chemical reaction, the obtained oxidized starch in addition to easy gelatinization, paste viscosity is low, good film forming adhesive strength, but also has the characteristics of high stability and transparency, good safety, etc., in food and other industrial fields widely used. Oxidation of starch is an important starch denaturation method. Oxidants can destroy α-1.4, a-1.6 glycoside bonds and hydroxyl groups in starch molecules, and oxidize them to carbonyl, aldehyde or carboxyl groups, so as to reduce the gelatinization temperature and viscosity of oxidized starch, improve its whiteness, transparency and bonding force, and make it form good film formation. Make oxidized starch have better use characteristics!

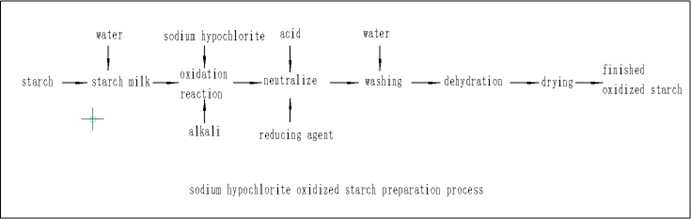

The process flow is as follows:

Effect of starch source on oxidation reaction

Starch is divided into two categories, amylopectin and amylose, amylose polymerization degree is generally several hundred, the degree of polymerization of amylopectin is generally more than 6000. The commonly used modified starch raw materials are wheat, corn, potato and cassava. The content of amylopectin in starch produced by any plant is more than 70%, among which: the amylose content in potato starch and wheat starch is low, and the amylopectin content is high; The content of amylopectin in waxy corn starch is about 100%. The content of amylopectin in cassava starch is slightly lower than that of potato starch and wheat starch. Some studies have found that the amorphous region of starch particles is the main place of oxidation reaction, and amylose is mainly concentrated in this region. Therefore, among these commonly used starches, waxy corn starch is the least susceptible to oxidation.

Effect of oxidation property of sodium hypochlorite on oxidation process

Sodium hypochlorite solution is also known as bleaching water, and ORP(REDOX potential) is the most intuitive parameter to reflect the oxidation of bleaching water. The key factor affecting the oxidation of bleaching water is its effective chlorine content, the effective chlorine content of industrial bleaching water is generally less than 10%, and the effective chlorine content of conventional bleaching water is generally 1.26%~10.36%. Under the condition of constant pH value, ORP of conventional bleach water increased first and then decreased as the available chlorine content decreased from 10.36% to 1.26%, showing a parabolic quadratic function relationship with an opening downward, and the oxidation of bleach water reached the maximum when the available chlorine content was about 7.7%. It can be seen that the higher the available chlorine content is not the better, and this result has also been verified in the experiment. Thus, subtle differences in the course of each oxidation reaction can be understood based on the available chlorine content.

Application of oxidized starch

Applications in food

In addition to oxidized starch in the pastry, the study found that oxidized starch can improve the elasticity of pasta, make the taste stronger, but also improve the appearance of the product color, and can effectively extend the shelf life. Adding acetylated oxidized starch to quick-frozen dumpling skin increased the hardness of dumpling skin and reduced the rate of frost cracking. The dumplings with and without oxidized starch were frozen for a period of time and thawed. It was found that the skins of the dumplings without oxidized starch were harder than those with oxidized starch, which also proved that oxidized starch could delay the aging of products and improve the quality of products. Oxidized starch prepared with sodium hypochlorite as oxidant can improve food quality on the one hand, and chloride produced by oxidation reaction has certain effects on human health on the other hand. Therefore, sodium hypochlorite oxidized starch was applied in food packaging. It has been found that adding oxidized starch can improve the tensile strength and elongation at break of the starch film. Studies have also shown that the use of oxidized starch to prepare starch film is one of the most effective choices.

Applications in industry

In the paper industry, starch is mainly applied on the surface of the paper in the form of rubber material to improve the smooth, easy to print, wear and grease resistance of the paper. It was found that adding 1.5% corn oxidized starch (base content 0.78%) could effectively improve the tensile index and rupture index of the paper, and the effect was good. In order to reduce the cost of water pinus base paper, the application of corn oxidized starch instead of cassava oxidized starch in water pinus base paper found that the two kinds of oxidized starch paper had the same surface status, similar printing effect and stable production operation except that the stiffness and surface strength indexes were slightly different, indicating that it was feasible to replace cassava oxidized starch with corn oxidized starch to reduce the production cost of water pinus base paper. Oxidized starch has low gelatinization temperature and is easy to gelatinization. Using this property, oxidized starch can be added as a binder to prepare compact ceramics. In the study of ceramic reinforcing agent, it is concluded that the organic reinforcing agent with good reinforcing effect is the main one in foreign countries, and the modified starch combined with inorganic reinforcing agent in China can also achieve good reinforcing effect and reduce the production cost.

Oxidized starch has the advantages of good gelatin transparency, strong bonding force, good fluidity, not easy to gel, etc. It is used in food and medicine, paper making, chemical industry and other industries, especially in the food industry, which can be used to make food-grade packaging bags and food additives.

Oxidized starch can be divided into potassium permanganate oxidized starch, hydrogen peroxide oxidized starch, sodium hypochlorite oxidized starch, etc. Among them, sodium hypochlorite oxidized starch is more common, and most of the chlorine-containing impurities in starch are degraded by sodium hypochlorite, so that colored substances are removed and decolorized. After long-term treatment with sodium hypochlorite, the unsaturated fatty acid content of starch is significantly reduced, the purity is improved, and the performance is improved. Sodium hypochlorite oxidized starch is widely used as dressing and mixing powder in mayonnaise, ice cream, salad dressing, soft pastries, starch jelly and bread, in the textile industry as warp sizing agent, in the paper industry as surface sizing agent, coating adhesive, wet end additive, corrugated board adhesive, in fine chemical industry as skin cleaning agent, antiperspirant, ball type antiperspirant, etc. Carpet cleaners, liquid gloves, skin protective oil sound, light-emitting paint blue fluorescent paint, adhesives, etc., used in medicine to treat azotoemia caused by various reasons and chronic nephritis, hypertension and diabetes caused by uremia. The results show that the starch film made from modified corn starch has the characteristics of high transparency, soft brightness, high tensile strength, etc. It is a good edible starch film material.

BLUEWAV sodium hypochlorite generator uses salt and water as raw materials to produce 0.8% sodium hypochlorite to 15% sodium hypochlorite, easy to use, cost-effective, and widely used.

BLUEWAV are a professional manufacturer of Sodium hypo machine , we have good experience on small plants and big plants up to 30 tons/day 12% HYPO.

Our company are specialized on disinfection & water treatment technology since year 2001, we research & develop & manufacture.

Reference: Modern Agricultural Science and Technology, No. 10, 2024; Article number: 1007-5739 (2024) 10-0131-04

Website :https://www.bluewaVv.com