At the seventy-sixth United Nations General Assembly, the General Secretary Xi Jinping put forward the global development initiative. We hope that all countries will work together to accelerate the implementation of the 2030 Agenda for Sustainable Development and build a global community with a shared future for development.

Recently, the journal Nature Communications published the latest results of a Chinese scientific research team on the feasibility and stability of the new principle technology of direct hydrogen production in seawater and the direct docking of green electricity at sea.

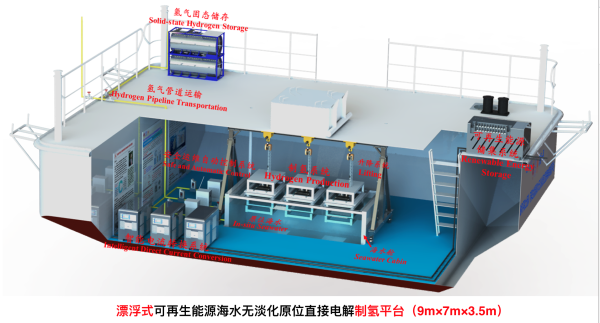

The direct electrolysis of seawater provides a new development idea for the future electrolysis of water hydrogen production, especially green hydrogen production. The results are based on the new principle technology of seawater in-situ direct electrolysis hydrogen production created by Xie Heping, academician of the Chinese Academy of Engineering, which is the first technical demonstration of direct hydrogen production by offshore wind power in the world, and the first time to realize the feasibility and stability of the new principle technology proposed by Chinese scholars in the real environment, and the first time to verify the feasibility of direct hydrogen production by offshore wind power without desalination against Marine environmental interference.

China Energy News reporter interviewed Xie Heping, academician of the Chinese Academy of Engineering and professor of Shenzhen University.

China Energy News: Hydrogen production by seawater electrolysis is increasingly attracting the attention of scientific research and industry. In your opinion, what are the advantages of seawater electrolysis for hydrogen production and what changes will it bring to the energy sector?

Xie Heping: The significance of hydrogen production by seawater electrolysis is reflected in three aspects: First, seawater resources are very rich. If hydrogen production by seawater electrolysis can be achieved, it will not be limited by land territorial boundaries and convert inexhaustible resources into green energy; Second, the direct consequence of global climate change is the rise of sea level, which will gradually reduce the land area of human survival in the future. If hydrogen production from seawater can be implemented on a large scale, carbon dioxide emissions can be greatly reduced, which may delay the rise of sea level to a certain extent. Third, with the large-scale preparation and application of green hydrogen in the future, the shortage of water resources may limit the development of electrolytic water hydrogen production. It is expected that in 2060, China’s hydrogen demand will reach 130 million tons, and about 2.3 billion tons of hydrogen production water will be consumed, which is equal to the annual water demand of Shenzhen, a city of more than 20 million people. Direct electrolysis of seawater to produce hydrogen does not require a large amount of fresh water resources, but also can promote the development of green hydrogen industry.

China Energy News: How do you view the future development direction and trend of seawater electrolysis hydrogen production technology?

Xie Heping: At present, there are two main technical directions for hydrogen production by seawater electrolysis: first, turn seawater into pure water or pre-treatment and then electrolysis hydrogen production, and second, direct electrolysis hydrogen production with seawater.

The technology of seawater desalination or pretreatment and then electrolysis for hydrogen production is relatively mature. In recent years, a number of demonstration projects are being built in our country. But this approach increases costs and energy consumption in two ways. The first is to turn seawater into pure water that can meet the quality of electrolytic water for hydrogen production, which needs to be pre-treated by sedimentation of seawater, and then pressurized for multi-stage reverse osmosis to push up the cost of hydrogen production process. Second, if the floating hydrogen production platform combined with floating wind power in the future, it is necessary to set up a water purification or pretreatment system on the floating platform, and the additional occupied platform area and load will increase the engineering difficulty of the system and the later maintenance and operation cost.

It is obvious that the direct electrolysis of seawater hydrogen production is expected to save the cost of seawater desalination and the engineering construction cost of hydrogen production system, and is a more potential future technical route.

BLUEWAV, China’s top sodium hypochlorite supplier, is committed to efficient and safe production of sodium hypochlorite, which can achieve a high concentration of 12% daily output of 30 tons per day. We can provide you with local technical support services in various regions, salt purity only needs 89%, the heart is better than action, please contact me!