Tannery industry produces a large amount of tannery sludge, which is classified as hazardous industrial solid waste in most countries because it contains a large amount of heavy metal chromium and sulfide. For a long time, the final disposal methods of our tanning sludge mainly include on-site stacking, landfill, incineration, production of various building materials and agricultural treatment. At present, there are three kinds of chromium removal technology applied in tannery sludge, which are physicochemical restoration, phytoremediation and microbial leaching. On the basis of summarizing the present situation of tannery sludge treatment, a method of leaching chromium from tannery sludge with sodium hypochlorite was put forward. This paper is an exploratory study on the treatment of tannery sludge by chemical oxidation, aiming to solve the restriction of heavy metal chromium, pathogens, parasite eggs and other substances on the agricultural use of tannery sludge.

According to its source, the sludge produced in tanning production can be divided into: immersed sludge, liming dehairing sludge, chromium-containing sludge and sludge produced by treating tannery wastewater. The main components of the immersed sludge are blood, mud and sand, etc. The main components of the depilatory liming sludge are sulfide, wool pulp, protein, lime, etc. Chromium-containing sludge and sludge left over from the treatment of tannery wastewater by physical, chemical and biochemical methods are mainly composed of: proteins, fats, chlorides of magnesium, chromium, calcium, sodium, sulfides, sulfates and a small amount of heavy metals (such as lead) salts. The harm of tanning sludge can be summarized as follows :① the harm of heavy metal chromium ② the harm of sulfide ③ the harm of pathogens and parasitic eggs ④ The moisture content of tanning sludge is large, easy to decompose and emit bad odor, so it is a very serious pollution source. From the perspective of sludge composition, if the organic matter content is rich, it is advantageous for sludge resource utilization. However, the presence of sulfide and heavy metal chromium has limited its resource utilization. Especially the heavy metal chromium has great potential harm to the environment. The toxicity of heavy metal chromium mainly depends on its valence state. Chromium in the environment mainly appears in three forms of chromium metal, chromium trivalent and chromium hexavalent. Chromium in tannery sludge mainly exists in the form of trivalent chromium, but some factors in the environment will convert trivalent chromium into hexavalent chromium. The main factors affecting the conversion between trivalent chromium and hexavalent chromium are: chromium form, concentration, oxidant or reducing agent, REDOX potential, ambient temperature, photoeffect, acid-base balance, complex agent and precipitation-dissolution balance. It has been reported that in fresh wet soil or under the action of oxidants such as manganese dioxide, chromium trivalent will slowly oxidize to chromium vi, and organic matter in the soil (such as soil humus and applied agricultural fertilizers, etc.) will slowly reduce chromium VI to chromium III. Therefore, the tannery sludge rich in heavy metal chromium has a huge potential harm to the environment. When people mention chromium pollution, they are not only concerned about the trivalent chromium content in the tannery sludge, but more concerned about the content of hexavalent chromium and the possibility of conversion from trivalent chromium to hexavalent chromium. The chromium content listed in this paper is the total chromium content, including both trivalent chromium and trivalent chromium.

Sodium hypochlorite can react with a variety of heavy metals, so it has a corrosive effect on metal instruments. In 2012, Kwang-Wook Kim studied the characteristics of the reaction of metals Ni, Co, Cu and Fe with sodium hypochlorite solution. It is pointed out that sodium hypochlorite solution can catalyze the formation of metal oxide-hydroxide from the above metals, in which nickel oxide is the most stable. In further experiments with nickel hydroxide, it is found that nickel hydroxide filled column can decompose the hypochlorite in seawater continuously and effectively. Studies by C.A. Baah and E. Pedulla have also shown that sodium hypochlorite solutions corrode stainless steel sinks containing chromium and instruments containing nickel and titanium.

Sodium hypochlorite treatment of tannery sludge is affected by different factors, such as: sodium hypochlorite concentration, liquid-solid ratio, reaction time, temperature, pH, light and so on.

The influence of sodium hypochlorite concentration:

1. Experimental procedure

(1) Use an electronic balance to weigh 1.000g of tanning sludge and pour it into four 250mL beakers with designated numbers.

(2) Use the analytical balance to weigh the concentration of 10%BLUEWAV sodium hypochlorite solution of 32 grams each, in which the diluted concentration of 3% and 6% and no dilution respectively. Add to the above three beakers, add another 32 grams of clean water (i.e. 0%) to the fourth beaker, stir for 15min, stand for 24h, filter with medium speed filter paper, and set the volume to 250mL, and determine the chromium content by ICP method.

(3) Calculate the chromium leaching rate: the leaching rate = the total chromium content of the leaching solution/the total chromium content of the tannery sludge ×100%

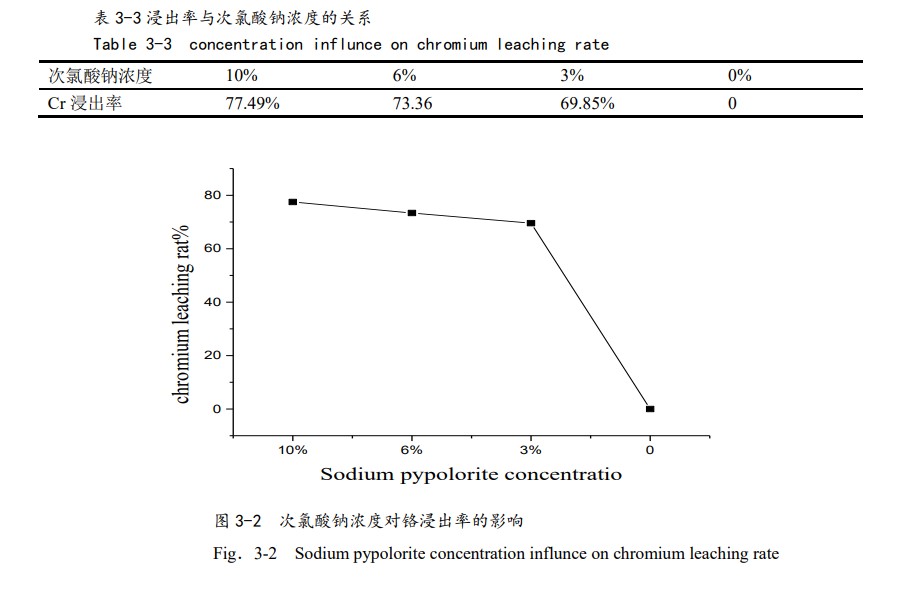

2. Experimental results and analysis

The results show that the influence of sodium hypochlorite concentration on the leaching rate is shown in Table 3-3. As shown in Figure 3-2, with the decrease of sodium chlorate concentration, the leaching rate will decrease, which can be attributed to the corresponding decrease of the effective chlorine concentration in the solution with the dilution of the concentration when the sodium hypochlorite dosage is fixed. This conclusion is the same as Li Xuanhai’s study on leaching gold with sodium hypochlorite. When the concentration of sodium chlorate is 0, it is clean water, and the chromium leaching rate is 0, indicating that the tannery sludge does not contain soluble chromium salt and chromium exists in a precipitated state.

The effect of feeding method:

The experiment on the effect of feeding method on leaching rate was carried out at room temperature 24℃, reaction time 24h, and the dosage of 10% sodium hypochlorite was fixed at 52 grams. In order to compare the reaction results, the reaction process was divided into two feeding methods. One is a one-time injection of 52 grams. The other is added in two times, each time 26 grams, the time interval is 12 hours. After the reaction, the chromium content was determined by ICP and filtered by medium speed filter paper. According to the formula of chromium leaching rate, the leaching rate of chromium was calculated. It is found that when sodium hypochlorite is divided into two times, the leaching rate of chromium can reach 84.14%, and the leaching rate of chromium is 63.18%, that is, the leaching rate of chromium is higher than that of one time. The above data analysis shows that since the decomposition rate of sodium hypochlorite is accelerated when the temperature is higher than 35℃, and the reaction of sodium hypochlorite leaching chromium is exothermic, it is easy to form a local overheat zone in the reaction system. The local overheating of the system will cause the decomposition of hypochlorite, resulting in a sharp decline in the concentration of sodium hypochlorite and a decrease in the leaching rate of chromium. In order to reduce the loss of hypochlorite, we should adopt the method of adding sodium hypochlorite step by step to improve the driving force of the leach process.

The single factor experimental study found that the sodium hypochlorite treatment of tannery sludge factors affect the concentration of sodium hypochlorite, liquid solid

Ratio, reaction time, temperature, PH, light, etc. The changing rules of these factors can be summarized as follows:

1. When other factors remain unchanged and only the liquid-solid ratio of sodium hypochlorite solution to sludge is changed, it is found that the chromium leaching of tannery sludge first increases with the increase of liquid-solid ratio. When the amount of sodium hypochlorite reached 32g solution /g mud, the Cr leaching rate decreased with the increase of liquid-solid ratio, that is, there was an optimal value of liquid-solid ratio in the process of sodium hypochlorite treatment of tannery sludge.

2. When other factors remain unchanged, when the dosage of sodium hypochlorite is fixed, and only the concentration of sodium hypochlorite is changed, the experiment found that the diluted sodium hypochlorite solution will reduce the chromium leaching rate, which can be attributed to the corresponding decrease of the effective chlorine concentration in the solution with the dilution of sodium hypochlorite dosage.

3. At room temperature, when other factors remain unchanged and only the reaction time is changed, it is found that with the extension of the reaction time, the chromium leaching rate gradually increases; After 24h, the leaching rate changed little. The reason can be considered to be room temperature, under the condition of no direct light, sodium hypochlorite basically decomposed after 24h, and the reaction tended to stop.

4. Since sodium hypochlorite is easy to decompose under high temperature or light and other factors, the method of adding sodium hypochlorite under the reaction condition of avoiding light and step by step is adopted. It can reduce the loss caused by the decomposition of sodium hypochlorite and increase the leaching rate of Cr.

BLUEWAV sodium hypochlorite generator uses automatic drug separation pump to add disinfectant in different times, reduce the loss of decomposition, remove heavy metal chromium, and contribute to the agricultural use of sludge.

Study on the removal of chromium from tannery sludge with sodium hypochlorite