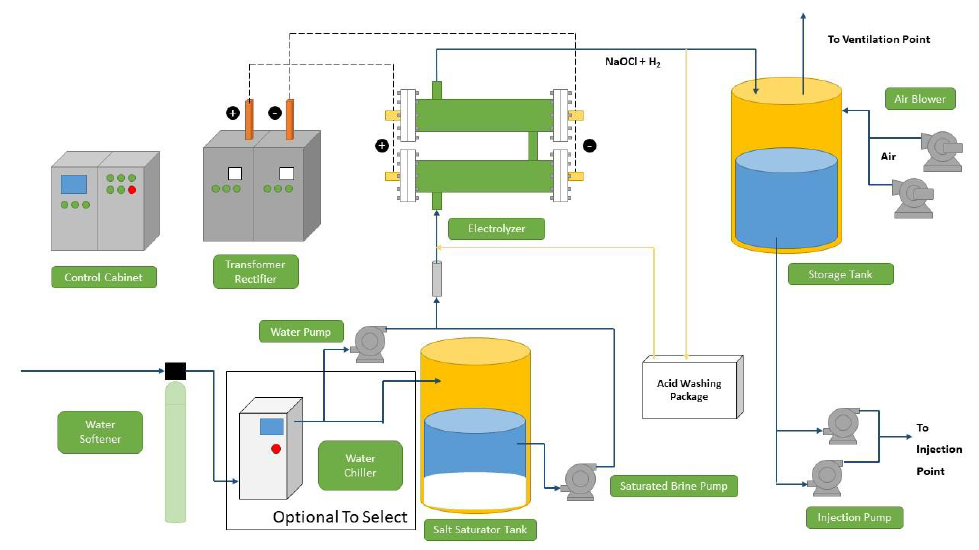

How it works

Sodium Hypochlorite Generator is a fully integrated, simple, and skid mounted designed system. The Chlory® technology uses a recirculating method to produce 0.8% strength sodium hypochlorite solution in 556lb(250kg) – 4500lb(2000kg) NaOCl/day by raw material input of Salt Brine.

How it installs

Chlory® Skid-Mounted design target on provide minimal operator attention for a quick Plug-Play running on site.

Install on site:

- Connect to the tap water pipeline;

- Connect the chlorination pipeline;

- Install hydrogen exhaust pipe

- Switch on the power supply;

System composition :

①Influent water passes through a water softener to reduce hardness therefore reducing the scaling of electrodes and lengthening the cleaning time.

② Salt is dissolved by softened water into saturated brine in the tank.

③ The saturated brine will be diluted into 2.5%-3%, then pass through the electrolytic cell and finally be electrolyzed into 0.8% solution of sodium hypochlorite.

④ The 0.8% hypochlorite solution flows into a storage tank. Hydrogen, the only byproduct of the process, is safely vented to the atmosphere.

⑤ Accuracy liquid dosed and controlled by residual chlorine analyzer.

| GBA-80-NACLO | GBA-100-NACLO | GBA-200-NACLO | GBA-300-NACLO | GBA-400-NACLO | GBA-500-NACLO | |

| Chlorine Capacity | 80g/hr | 100g/hr | 200g/hr | 300g/hr | 400g/hr |

500g/hr |

|

Water treatment Capacity(At 1ppm dosing) |

1MLD | 2MLD | 4MLD | 6MLD | 8MLD |

10MLD |

|

Salt Consumption |

3.5kg/kg Cl2 | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 |

3.5kg/kg Cl2 |

|

Power Consumption |

4.0kw/kg Cl2 | 4.0kw/kg Cl2 | 4.0kw/kg Cl2 | 4.0kw/kg Cl2 | 4.0kw/kg Cl2 | 4.0kw/kg Cl2 |

| Concentration of HYPO | 5000ppm | 5000ppm | 5000ppm | 5000ppm | 5000ppm |

5000ppm |

|

Production Flow Rate |

10L/hr | 20L/hr | 40L/hr | 60L/hr | 80L/hr |

100L/hr |

.jpg)