How it works

The Chlory® offshore electrolytic seawater chlorine production systems are basically skid-mounted and integrated. The complete system adopts a pickling-free concentric circular tube (CTE) electrolytic cell, which can avoid the use of hydrochloric acid in the offshore state and eliminate the tube-sheet electrolysis, troubles and worries caused by pickling of tanks and hydrochloric acid storage.

Special designs can be provided according to the relevant design standards and certification requirements of third-party certification bodies such as DNV-GL, BV, ABS, etc. For details, please consult our engineer for more information.

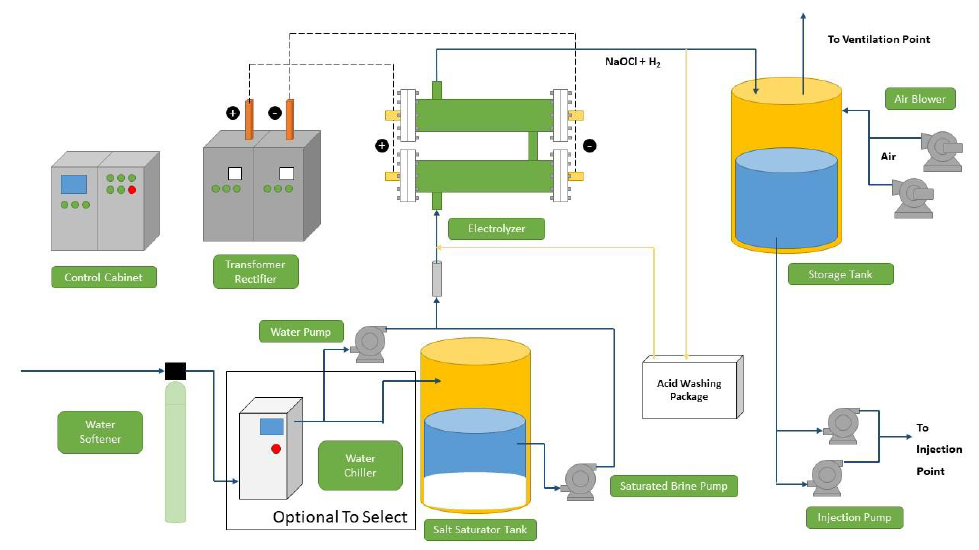

System composition

|

Sea water filtration system |

The seawater is filtered to micron level to prevent large particles from entering the electrolyzer group and affecting the electrolysis process. |

|

Electrolyzer group |

The electrolytic cell group is the core unit of the whole set of equipment. The electrolytic cell group adopts titanium-based ruthenium and iridium rare metal oxide coating. The seawater passes through the electrolytic cell group through direct current catalysis to convert seawater’s sodium chloride into sodium hypochlorite and hydrogen. |

|

Rectifier transformer |

Usually a rectifier transformer in the form of a silicon controlled rectifier is used, the voltage is changed to the required voltage through the transformer, and then a thyristor is used for controlled rectification. The input AC power is converted into DC power and the positive and negative poles provide power source and output to the electrolytic cell. |

|

Storage and dehydrogenation tank |

The generated sodium hypochlorite solution and hydrogen enter the storage and dehydrogenation tank through the pipeline for temporary storage and dehydrogenation process. |

|

Dehydrogenation fan unit |

The wind unit generally adopts the1D+1Sform,which blows a large amount of air into the storage and dehydrogenation storage tank to dilute the produced hydrogen and provides a power source to discharge the diluted hydrogen to a safe discharge point. |

| Dosing pump set |

Use corrosion-resistant centrifugal pump to output to the dosing point. |

|

Control System |

The central control system of the complete set of equipment is used to control the automatic start and stop of the complete set of equipment and coordinated control with the outside. |

| Power distribution system |

Allocate power sources for motors and related electrical drive equipment. |

|

Optional accessories |

1. Seawater booster pump set 2. Electrical system solutions for explosion-proof areas 3. HAZOP(Dangerous feasibility analysis) meeting 4. Third-party certification |

Application field

|

Petrochemical |

Offshore platform |

|

Ship |

Ballast tank water treatment |

|

Subsea storage water treatment |

Specification

|

Electrolyzer form |

Bipolar – Concentric tube |

| Accessories material |

ABS (or PVC), EPDM and titanium |

|

Anode substrate |

Titanium ASTM B 338 GR.1 or 2 |

| Anode coating |

Rare Metal Oxide (MMO) |

|

Cathode substrate |

Titanium ASTM B 338 GR.1 or 2 |

| Cathode coating |

N / A |

|

Bipolar titanium tube substrate |

Titanium ASTM B 338 GR.1 or 2 |

|

Bipolar titanium tube anode coating |

Rare Metal Oxide (MMO) |

| Seawater flow |

≥5.6 m3/Hr |

|

Design liquid temperature of electrolyzer |

5 to 55 degrees Celsius |

| Ambient temperature of electrolyzer design |

0 to 85 degrees Celsius |

|

Design pressure of electrolyzer |

10 Bar |

Flow Chart